We are pleased to inform you that our Value Pick stock - Technocraft Industries Ltd (BSE Code: 532804, NSE Code:TIIL) which we recommended on 19 March 2023 at Rs. 1165 has achieved its target price of Rs. 1750 in just 2 months.

Technocraft Industries stock made its all time high of Rs. 1779.35 recently and closed at Rs. 1753 today giving absolute returns of 50% to our Value Picks members in period of 2 months. We have not suggested any profit booking in the stock to our members, as we expected the company to perform well in coming quarters. Technocraft Industries will report its March quarter results on 29 May 2023.

Below is the report of Technocraft Industries Ltd released by our team as Value Pick stock on 19 March 2023, the report was shared with all our Value Picks members.

1.

Company Background:

Technocraft

Industries was established by two IIT Graduate brothers as a partnership firm

in 1972 which later converted to a private company in 1991. Technocraft

Industries India Limited was initially focused on manufacturing high precision

and sophisticated Drum Closures products for domestic markets but later the

focus shifted to exports. The company was recognized as an export house by the

government of India in 1979 and that’s when the company started establishing

its subsidiaries in USA and Europe to cater the local market. In the year 1994,

the company started expanding the product portfolio by acquiring Maharashtra

Steel Tubes Ltd which was into manufacturing of Steel Pipes. Steel Pipes were

hugely imported in Europe and to cater the opportunity, the company opened an

office in United Kingdom at that time. Following the path of diversification,

the company entered into manufacturing of cotton yarn in 1997. The yarn

division was focused on manufacturing and export of 100% cotton ring spun yarn

and was accorded a 100% EOU status.

Today,

the company operates its business activities broadly in 3 divisions:

- Drum Closures

- Scaffolding & Formwork

- Textiles (Cotton Yarn &

Garments)

i)

Drum Closures - The

company is one of the leading manufacturers of Drum Closures worldwide and has

established a worldwide market share of around 36% excluding China. The company

is reputed globally for its quality and range of products it offers for drum

closures. The company supplies drum closures to most leading drum and drum part

manufacturers in the world including - B-POL, Drum Parts Inc, Mauser

Group worldwide, Schutz Group worldwide and August Berger

Metallwarent Gmbh. The ultimate end-user industries predominantly include oil

and gas, packaging, chemicals, and food and beverages.

ii)

Scaffolding & Formwork -

Next big division of the company is Scaffolding and Formwork. Scaffolding is a

temporary structure used to support people and material in the construction

industries, real estate and any other large structures. It is usually a modular

system of metal pipes or tubes, although it can be from other materials also. Formwork

is the term given to either temporary or permanent molds into which concrete or

similar materials are poured. This segment earns around 70% of it’s revenue

from the overseas market. Scaffolding division is the second highest profit

generator for the company, next to only drum closures.

iii)

Textiles (Cotton Yarn & Garments) - The company has a State-of-the-art cotton yarn spinning

mill equipped with fully automatic sophisticated technology from Germany,

Switzerland, Japan and Spain near Mumbai. The plant is producing 30000 kgs of

yarn per day on 61000 spindles installed and exporting to markets like South

East Asia, China, Far East, Africa, Europe and Latin American countries.

Technocraft

industries also deals in Fabric and Garments production. This division is

moving towards a turnaround resulting from structural changes undertaken

by the company to improve operating efficiencies. Being part of a diverse

group, the Company has access to the latest trends in the European markets,

thus enabling it to offer high quality products and latest fashions with Indian

prices in a very short lead-time. As a result of this, 56% of total garments

produced is exported to European, Asian and Latin American market.

Certifications:

The

company is equipped with various certificates obtained for various divisions

which ensures quality of products. Following are listed to name a few:

- IS/ISO 9001:2015 Certificate

of Pipe division

- EN 1090-2:2018 Welding

certificate for Steel products

- EN 1090-3:2019 Welding

certificate for Aluminum products

- EN ISO 3834-2:2006 Welding

certificate for Metallic materials

- TechEuro-II props certified

as per EN 1065:1998

- TechEuro-III props certified

as per EN 1065:1998

- Certificate of Approval for

Japanese Industrial Standards

- TUV Austria OHSAS 18001:2007

certificate for Garment division

- TUV Austria EN ISO 9001:2015

certificate for Garment division

- TUV Austria EN ISO

14001:2015 certificate for Garment division

- OEKO-TEX Standard 100

certificate for Garment division

Management

Profile:

Mr.

Sharad Kumar Saraf (Chairman cum Managing Director) - Mr. Sharad Kumar Saraf

holds a degree in Electronics Engineering from IIT Bombay, graduated in 1969.

Before founding the company, Mr. Sharad underwent one year industrial training

in Germany in 1970 and returned to form Technocraft. Mr. Sharad has held

various positions in different public organizations like Federation of

Indian Export Organisations (FIEO), Confederation of Exporting Units

(CEU), Indo-Romanian Chamber of Commerce, The Council of EU

Chambers of Commerce in India etc.

Mr. Sudarshan

Kumar Saraf (Co-Chairman cum Managing Director) - Mr. Sudarshan too is a

IIT Bombay graduate holding a degree in Mechanical Engineering is responsible

for directing all the engineering operations of the group. He was conferred the

distinguished service award for the year 1999 by the Institute of Technology,

Bombay. He pioneered the development of interval thread rolling process and

built tools which were introduced in America which enabled the customer to save

on labor cost and gain better yield.

Mr. Naveen

Kumar Saraf (Director and CEO) - Mr. Naveen holds a degree from

University of Manchester in Mechanical Engineering. He led the diversification

of group into value added scaffolding and formwork which now holds a valuation

of USD 80 million by the firm. He envisioned the diversification into engineering

services outsourcing segment which is run through a subsidiary and employs more

than 500 engineers in India, USA, Canada, UK and Germany. He is an active

member of Young Presidents organization (YPO) and The Indus Entrepreneurs

(TIE).

Mr. Ashish

Kumar Saraf (Director) - Mr. Ashish Kumar Saraf holds a bachelor degree

in commerce from University of Mumbai and a Masters in Textile Technology

degree from Manchester University. He also completed a course on Cotton

Management from Rhodes Institute, Memphis, USA.

2. Recent

Developments / Market Outlook: (as on 19 March 2023)

i)

Technocraft Industries Board of Directors approved the Buyback Proposal

The

Board of Directors of the company at its meeting on November 14, 2022, has

inter-alia approved the proposal of Buyback.

The proposal to buyback not exceeding 15,00,000 (Fifty

Fifteen Lakh) equity shares of face value of Rs. 10 of the Company

(representing 6.13% of the total number of equity shares in the paid-up share

capital of the Company) at a price of ~1000 (Rupees One Thousand Only) per

equity share payable in cash for an aggregate consideration not exceeding 150

Cr (Rupees One Hundred Fifty Crore Only). The buyback opened on 1 February 2023

and closed on 14 February 2023.

In

accordance with the provisions of Regulation 24(iv) of the Buyback Regulations,

the equity shares bought back by the company during the tendering period were

extinguished. Post extinguishment of 15,00,000 equity shares of the company, the

total number of shares were reduced from 2,44,61,687 (Prior to the Buyback - as

of the Record Date, being December 30, 2022) to 2,29,61,687.

ii)

Global Steel Drums market is expected to grow at CAGR of 4.5%

The

global steel drums market is expected to hit USD 22.5 billion by 2029,

expanding at a CAGR of 4.8% from 2022 to 2029. Increasing global trade and

investment in efficient transport are expected to support the market growth in

the forecasted period. Increasing global demand for food supplies and pharmaceutical

segment produce is expected to take a major share in transport. With more

demand for drums, closure’s demand will follow. Each drum requires one set of

closure and may require gaskets and clamps for better fitting which are also

produced by the company. With a variety of drum closures range according to the

needs of the customer, the company is expected to strengthen its hold of the

market.

iii) Global Scaffolding market is

expected to grow at a CAGR of 6.3%

Global

scaffolding market is expected to grow at a CAGR of approximately 6.3% from

2020 to 2027. Increasing FDI in construction in the Asia Pacific region and

supportive government regulations and policies are driving the scaffolding

market. The Indian government in its annual budget emphasized majorly on

capital expenditure and development of infrastructure around the country. This

construction will induce the demand for scaffolding and formwork division

produce.

iv) The Indian Textile & Apparel

Exports has a 4% share of the Global Trade

The

Indian textile market is expected to be worth more than USD 209 billion by

2029. For perspective, the market stood at USD 152 billion in 2021.

India is the world’s largest producer of cotton. Estimated production

stood at 362.18 lakh bales during cotton season 2021-22. Production for next crop year is expected to be

around the same volume as it was in preceding crop year. Domestic consumption for the 2021-22 cotton season is estimated to be

at 338 lakh bales. Cotton production in India is projected to reach 7.2 million

tonnes (~43 million bales of 170 kg each) by 2030, driven by increasing demand

from consumers. Also, export of textiles grew by a healthy rate of 9%.

Hence the demand, revenue and profits are expected to grow in future.

The

government has targets of raising the share of the manufacturing industry in

Gross Domestic Product up to 25% by 2025. The introduction of PLI schemes is a

way to push towards the goal. Currently, the sector contributes about 14.43% in

2021. The Indian manufacturing sector is steadily moving toward more automated

and process-driven manufacturing, which is projected to improve efficiency and

enhance productivity. Also, the push towards “Make in India” is expected to

help the government achieve or reach close to the target.

3. Financial Performance: (as on 19 March 2023)

i) Quarterly Results Analysis: Quarterly consolidated revenue and consolidated

profits of the company are showing impressive results. The company managed to

increase its quarterly revenue for the period ending June 2022 by 33% compared

to last year and by 8% in September 2022. Although quarterly revenue for the

period ending December 2022 dipped compared to same period last year, the

company managed to improve profit by 33% mainly due to improved operating

profit margins. The chart shows the improvement in operating margin over the

quarters

In Dec’23 quarter, while the Drum Closure business

saw pressure on the profit margin due to increased cost of materials, ocean

freights and other inflationary impact on consumables & services along with

pressure on demand, the Scaffolding business performance witnessed substantial

improvement. The company is observing strong demand for its product and as a

result there is substantial increase in Revenue and Margins.

The Textile segment of the company

observed pressure on revenue as well as on margins due to increased cost of raw

material (Cotton) & reduced price of finished product (Yarn)

ii) Balance

Sheet Analysis: During the year, the company reduced its long term borrowings in order to

reduce the interest costs and instead shifted towards more short term loans. On

analyzing further, we can observe the nature of short-term loans are majorly in

the nature of Packing Credit. Packing Credit is a short-term loan facility

which a manufacturer can use to fulfil orders. This loan can be used to acquire

raw materials required for a particular shipment and paid back when the amount

is received from the customer, hence these are generally without security.

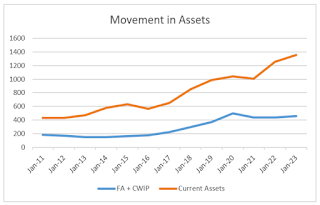

As illustrated in the

chart above, there is a consistent increase in value of assets held by the

company. Both fixed and current assets are following the same trend. The

company has slightly improved debtor days and inventory days indicating

efficient use of funds.

4. Investment Rationale: (as on 19 March 2023)

i)

Technocraft Industries has designed and developed the next generation

technology for manufacturing of drum closures. It also manufactures all its

gaskets and clamps and offers a full range of drum closure products to its

clients. With patented technology, there has been substantial reduction in

manufacturing costs, improvement in quality and this has helped the company to

become the second largest global manufacturer of steel drum closures.

Technocraft Industries is the second largest manufacturer of steel Drum

Closures and continues to enjoy a worldwide market share of about 36%

(excluding China). The company produces a wide variety of closures and related

equipment ranging from fully automatic flange insertion systems to cap-sealing

tools. The company caters to all leading steel drum manufacturing companies of

the world.

ii) Technocraft

Industries is also a leading Indian manufacturer and distributor of

scaffoldings and formwork systems. The company has been supplying scaffoldings

to global markets for over 20 years. Despite the volatile nature of

construction and allied activities, the Scaffolding & Formwork (S&F)

market is thriving in India and is expected to see brighter times ahead. With

the demand rising in the wake of ongoing and future projects, S&F

manufacturers are keeping pace with the construction industry. The company has

strategically located state-of-the-art manufacturing facilities with installed

capacities of 40,000 MT and 25,000 MT in India and China, respectively. The

company is positioned as an end-to-end solution provider owing to its

well-integrated manufacturing capability. The company supplies its products to

a diversified set of end markets including oil & gas, power, refineries,

petrochemical, infrastructure and commercial construction.

iii) Looking at

the Indian government’s focus on rapid infrastructural development across the

country by constructing railways, roads, bridges, dams, airports, power plants

and many more, construction is expected to grow at a fast pace. Contractors

have started adapting newer technologies, faster systems, advanced concrete

techniques and better and established management tools. Engineered formwork

systems are built out of prefabricated modules with a metal frame - usually of

steel or aluminium - and covered on the application (concrete) side with

material having the wanted surface structure (steel, aluminium, plastic,

timber, etc)

iv) The company

has entered into manufacturing of sophisticated engineered formwork systems for

building, construction and infrastructure projects in India. The company has

state-of-the-art manufacturing plants in India and is well placed to play a

larger role in the construction growth in India and overseas, with a network of

offices at Mumbai and overseas. The company’s

product ‘Mach One’ is a very lightweight Formwork system made of high quality aluminium

extrusion with admirable strength to take on the site conditions. Mach One aluminium

forms are best suited for construction of residential units and mass housing

projects. As per industry reports, 80% of the total cost of scaffolding is

attributed towards labor cost that is involved in loading and unloading and

erection and dismantling of scaffolding. With Mach One, the company has made

this cost more efficient by making the entire system lighter without

compromising on the required strength.

v) The company has

a yarn division having consolidated capacity of around 87,000 spindles. The company

produces a variety of products ranging from NE 20 to NE 40, carded and combed

varieties of cotton yarn. The spinning mill is equipped with world-class Swiss,

Japanese, German, Spanish equipment.

Currently, the company exports around 55% of garment products mainly in

Europe, Asia, Latin American countries etc. This company has made significant

structural changes in this division like grey cotton yarn operations are now

based in Amravati which is cotton growing area and has cost effective

operations and has shown substantial improvements in revenue as well as

profits. In Murbad, the company now produces only value- added high margin

products like melange yarn and fabric. These are also generating substantially

better revenue and profit. Overall, this division has now been re-engineered

and all loss making products and locations has been plugged by the company.

vi) Technosoft

Engineering Projects Limited is a subsidiary of the company. It is a global

technology services company offering broad-based engineering, designing and IT

services using a variety of client-partnership models for delivery. Technosoft

Engineering Projects client base spans various industry verticals including

heavy machinery, automotive, aerospace, manufacturing, oil & gas,

high-tech, telecom, healthcare and financial services. The company’s client

base is widely spread globally including many clients from US, Canada, UK and

Germany. This subsidiary has a strong team of over 300 engineers and designers

located worldwide. Its engineers and designers are equipped with

state-of-the-art hardware and software tools, including tools for 3-D modeling,

Finite Element Analysis and process simulation.

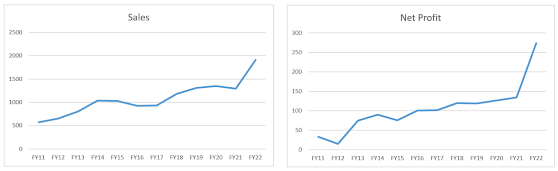

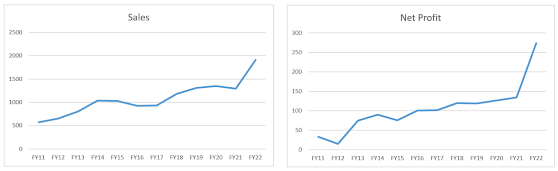

vii) The consolidated revenue of the company is

consistently increasing over the years and the same trend is followed by the

profits. As illustrated in the charts below, revenue has reached around 2000 crore

in FY22 and is expected to surpass even that in FY23. The consolidated profit

is also expected to grow with expected turnaround in the textile division. With

improved operating profit margins in last few years, profit jump looks higher

than the revenue.

viii) Infrastructure

projects have taken pace globally after a slowdown during the pandemic period.

Infrastructure industry growth will induce the demand for scaffolding and

formworks. The innovative scaff shelter product recently introduced by the

company which erects temporary labor shelters within a few hours will be in

demand with new projects. The company claims to set up an on-site facility for

100 workers in 7 days with its scaff shelter facility. The scaffolding and

formwork made by the company is considered to be a premium product due to its

quality. In recent years, the market has seen a shift towards premium and more

reliable products, especially in long term projects. Hence, the company has an

advantageous position with a reputation of being a manufacturer of high-quality

products.

ix) Technocraft Industries is upgrading and

expanding its capacity in the textile division. As mentioned earlier in the

report, the company has implemented structural changes in the textile division

to improve operating efficiency. The company expects a turnaround in this

segment in future and if turned profitable, it will bring big boost towards

margins and overall profitability of the company. Moreover, through the textiles

business the company has diversified its business operations by reducing its

dependence on other divisions.

x) Technocraft Industries has a strong track

record, the company has achieved sales CAGR of 15%, profit CAGR of 21% with ROE

of 16% over the last 5 years. At current price of Rs. 1165, the company is

available at price to book value of 1.94 and is commanding PE multiple of 9.4

on trailing 12 months basis. The company has

improved debtor days, inventory days and creditor days in FY22. These ratios

indicate better utilization of funds and efficiency in operations. Moreover,

current ratio over 2 times, interest coverage ratio over 16 times and

comfortable debt to equity of 0.34 times indicates fundamental strength of the

company.

xi) Post completion of buyback, the promoters

shareholding in the company is at 74.61 percent. As on Dec’22, institution

shareholding in the company is 4.79 percent, out of which alternate investment

funds hold 4.02 percent stake (Aequitas Equity Scheme holds 1.05 percent and

Abakkus Emerging Opportunities fund hold 2.97 percent) and foreign portfolio

investors hold 0.77 percent stake in the company.

5. Key

Concerns & Risks: (as on 19 March 2023)

i) Global recession concerns:

As per the world bank, economies around the world will be facing challenging

times in the coming period. The world bank predicts the US economy to grow by

only 0.5% and Europe market growth to remain flat or zero. The company’s

majority revenue is earned by exports and US and Europe are considered to be

their largest markets. Slowdown in these economies is going to affect

Technocraft’s performance.

ii) Weakening of INR: Indian rupee has touched an all time

low against US Dollar in October 2022. 70% of the revenue of Technocraft comes

from export sales and the US Dollar is considered to be the predominant

currency in global trade. This weakening of INR can impact the operating

margins of the company in large competitive markets.

iii) Loss in Fabric segment:

The company has been

constantly reporting losses in Fabric segment. Garment industry is considered

to be one of the most populous industries in the world and this is affecting

the overall profitability and overall operating margins of the company.

Although the company has almost halved the losses in FY22 compared to FY21 with

increased turnover by 64% in the same period, the losses are expected to widen

in FY23 based on the limited segment wise information provided by the company

in December quarter results.

6. Saral

Gyan Recommendation: (as on 19 March 2023)

The

company focus is to grow its position in each of its core businesses which is

Drum Closures, Scaffolding, Engineering & designing Services and Textiles.

The company sees the Drum Closure division growing at a robust pace and is one

of its core focus areas. The company is working strongly and increasing the

sales and profitability in China which is one of the main growing markets for

Drum Closures division. Scaffolding business is also expected to do well

considering Government initiatives such as RERA, Affordable housing, Smart

Cities etc. which is expected to bring a transformational shift and boost

growth of the Indian real estate industry. The company believes that this division has strong future prospects due to

anticipated growth in infrastructure and affordable housing construction demand

in India as well as globally. Moreover, the company has implemented

structural changes in the textile division to improve operating efficiency. The

company expects a turnaround in this segment in future and if turned

profitable, it will bring a big boost towards margins and overall profitability

of the company.

Considering

consistent increase in profits and margins in the past with significant

increase in net worth of the company (net worth as at 31 March 2016 was Rs. 553

crores which has substantially increased to Rs. 1330 crores as at 31 March

2022), planned capacity expansions in the textile

division and diversifying into plastic drum closures to drive future growth,

expected volume growth in the scaffolding division with increasing thrust on

infrastructure development and reasonable to attractive valuations of the

company, Saral Gyan team recommends “Buy”

on Technocraft Industries (India) Limited

at a price of Rs. 1164.55 for a target of Rs. 1750 over a period of 12 to 24

months.

Buying Strategy:

- 60% at current market price of 1164.55

- 40% at price range of 900 – 1000 (in case of

correction in stock price)

Portfolio

Allocation: 3% of your equity portfolio.

If you wish to invest in fundamentally strong micro, small and mid cap companies which can give you far superior returns compared to major indices like Sensex or Nifty in long term and help you creating wealth, you can join our services like Nano Champs, Hidden Gems, Value Picks & Wealth-Builder.

The stocks we reveal through Nano Champs, Hidden Gems & Value Picks are companies that either under-researched or not covered by other stock brokers and research firms. We keep on updating our members on our past recommendation suggesting them whether to hold / buy or sell stocks on the basis of company's performance and future outlook.

Moreover, under our Wealth-Builder service, we encourage our members to replicate our Wealth-Builder portfolio by investing in selective high quality small and mid cap companies. We believe, investing in Wealth-Builder portfolio with regular portfolio review from our end can help you achieve market beating, very good returns over a longer team and help you take care of yourself and your family needs, which ultimately lead to a healthy and wealthy life after retirement.

Great News! If you are a new user, you can avail a discount of 10%. Simply, enter discount code - NEWUSER10, to avail flat discount of 10% on individual services and additional discount of 10% on combo packages.

SARAL GYAN SUBSCRIPTION SERVICE |

ANNUAL SUBSCRIPTION PRICE | PAY VIA CREDIT CARD (3% CHARGES EXTRA) |

|---|

| Hidden Gems | Rs. 14,000 | |

| Value Picks | Rs. 8,000 | |

| 15% @ 90 Days | Rs. 5,000 | |

| Wealth-Builder | Rs. 28,000 | |

| Combo 1: HG + VP + WB + 15% | Rs. 55,000 44,000 (20% OFF) | |

| Combo 2: HG + VP + 15% | Rs. 27,000 22,000 (20% OFF) | |

| Combo 3: HG + VP | Rs. 22,000 19,000 (14% OFF) | |

| Combo 4: HG + 15% | Rs. 19,000 17,000 (11% OFF) | |

| Combo 5: VP + 15% | Rs. 13,000 11,500 (11% OFF) | |

SUBSCRIPTION OPTION | PAY VIA CREDIT CARD (3% CHARGES EXTRA) |

NANO CHAMPS – 1 YEAR - Rs 12,000 | SUBSCRIBE |

NANO CHAMPS – 3 YEARS - Rs. 30,000 | SUBSCRIBE |

Note: To subscribe to our annual subscription services, follow below steps:

i) Click on SUBSCRIBE link,

ii) Enter discount code NEWUSER10 to claim discount of 10 percent,

iii) Enter your debit / credit card details to complete the transactions.

Hurry! Discount code NEWUSER10 is for limited period only and expires soon.

Click here to know more about our services and discounts applicable on combo packs.

Do write to us in case of any queries, we will be delighted to assist you.

Regards,

Team - Saral Gyan

Home

Home Saral Gyan Freebies

Saral Gyan Freebies Saral Gyan Services

Saral Gyan Services About Us

About Us Contact Us

Contact Us